Process & Quality Control

At our DXP Babbitt bearing shop, we perform a complete process for every bearing repair and every job, closely following our written in-house procedures and specifications. For example, for a large steam turbine journal bearing repair, we complete the following steps for every repair:

- Incoming Inspection - The bearing is uncrated and visually inspected, with photo documentation. A job order is created with a shop traveller, and any specific customer requirements or specifications reviewed. A complete dimensional inspection is made and recorded. If the bearing drawing is not already in our extensive files, a sketch and then CAD drawing is created detailing all bearing dimensions and profiles, including oil supply and drain holes and grooves, slips, and bore profiles.

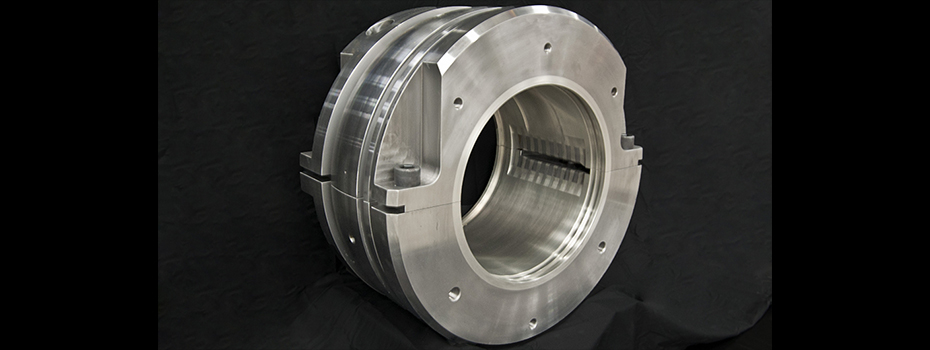

- Repair Preparation - The bearing babbitt is machined out, not melted, with all shell dovetails and profiles maintained. Shell repairs, if needed, are completed.

- Recasting - The bearing is prepared for casting by fabricating a spin casting frame. Once mounted on the spin casting machine, the shell temperature is carefully controlled, and spin casting speed are carefully controlled using our variable frequency drive. The shell is tinned, and the bearing cast using only new, unused babbitt material.

- Machining - The bearing bore is machined with one of our vertical or horizontal mills, with correct shims used for elliptical bearings. Oil drain grooves, supply holes, and lift oil grooves are machined in according to the drawing.

- Final Inspection - Upon completion, the finished bearing is fully inspected. A complete UT and PT inspection is completed and recorded; a complete dimensional inspection is recorded. Final photo documentation is created. All process documentation is assembled into a complete report.

- The bearing is protected and crated, and ready for shipping.

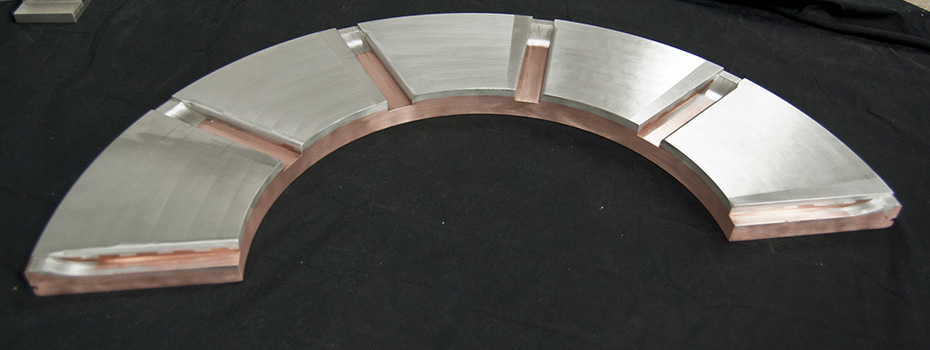

The above general outline is a summary of our journal bearing repair process. But we also rigidly follow our written procedures for thrust bearing repair or new fabrication, tilt pad journal bearing repair or new fabrication, static casting and TIG repair processes. We can review these at your convenience, and we also welcome shop and work inspections. We look forward to your visit!

Specifications and Quality Control

At DXP Babbitt we use and follow written procedures for every repair and manufacturing job we perform. We will review these with customers at their request and convenience. We can also follow customer repair specifications as directed. As many plants and customers continue to develop their own in-house procedures and specifications, our engineers can help with the development of your documents; we don’t mind sharing our highest quality practices!